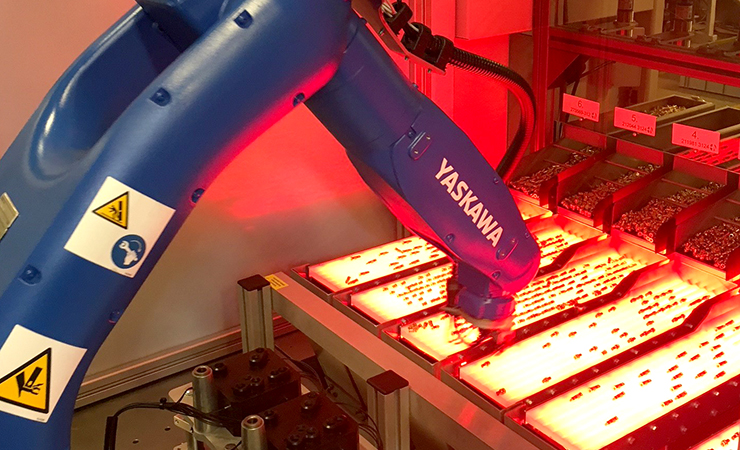

HN Group A/S places considerable focus on the use of robots as a technological springboard. One of the specialities that has emerged in this area is the combination of metal and plastic. Stainless steel punched parts are fed through to a six-armed robot which works in collaboration with the machine robot to perform an advanced piece of work for embedment of the metal part.

It is currently being tested at a facility where 16 threaded bushings in six varieties are loaded into a moulding tool and recast. The solution involves a six-armed robot that works in collaboration with vision cameras that identify positions for the robot.

"We have managed to solve the task in close collaboration with our automation partner Blaaholm, in line with the requirements we have committed ourselves to. Blaaholm has proven to be a competent partner that has been able to contribute the latest technologies to our existing production process", says CEO Allan Hansen.

Allan Hansen continues: "The task placed high demands on the tool’s functionality and precision, in addition to its service life. Hjernø Værktøjsfabrik was our natural choice of partner in this regard, and they were great at sparring with us throughout the whole process".

Do you manufacture products which entail excessive costs for manual assembly? Let us tell you about the solutions we can offer. Contact Allan Hansen by telephone at +45 40 88 17 58 or send an email to ah@hngroup.dk.